What is the function of the high current test pin? How to do maintenance?

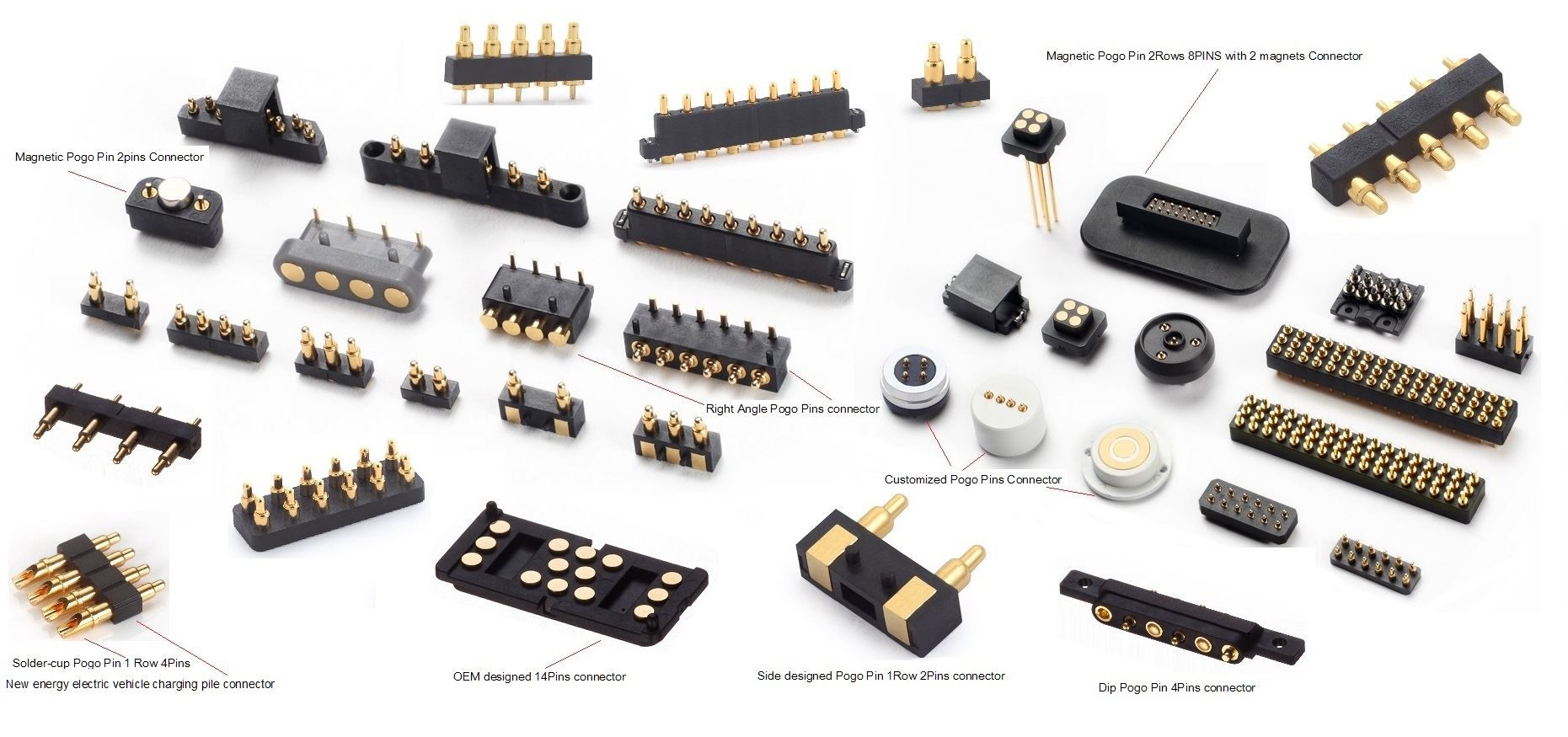

High-current test pogo pins can meet various test requirements. In many industries where high current is used, high current probes are required. First, they are widely used for various functional testing, signal transmission, production testing, and as built-in shock components. Second, the test requires a high-current test pin with low internal resistance. For example, BTB/FPC connectors can carry large currents while maintaining a stable connection.

Intrinsic factors such as the probe core area, material conductivity, and insulating layer conductivity of the high-current test needle determine the current-carrying capacity of the probe. The thicker the probe, the higher the purity of copper in the conductive material, the better the thermal conductivity of the insulating material, the higher the conductivity of the high-current test probe, and the greater the current-carrying capacity.

In addition to some external factors that can cause the probe ampacity to decrease in a specific environment, what can determine the ampacity of the high-current test needle is the internal factor of the probe, which mainly includes the following three decisions;

1. Thermal conductivity of the insulating layer

In addition to preventing electric shock, the insulating layer has another important role as protection against electric shock. The better the thermal conductivity of the insulating layer, the better the flame retardant performance. Therefore, the quality of the insulating material determines the current carrying capacity of the probe from another aspect.

2. Material conductivity

Here it depends on the conductor material, such as common copper wire and aluminum wire. Copper materials are at least 30 percent more conductive than aluminum. Silver lines may appear when necessary. In addition to the substance of the material, it also depends on the purity of the material. Taking copper as an example, high-purity red copper has much higher conductivity than inferior brass.

3. Probe the core area

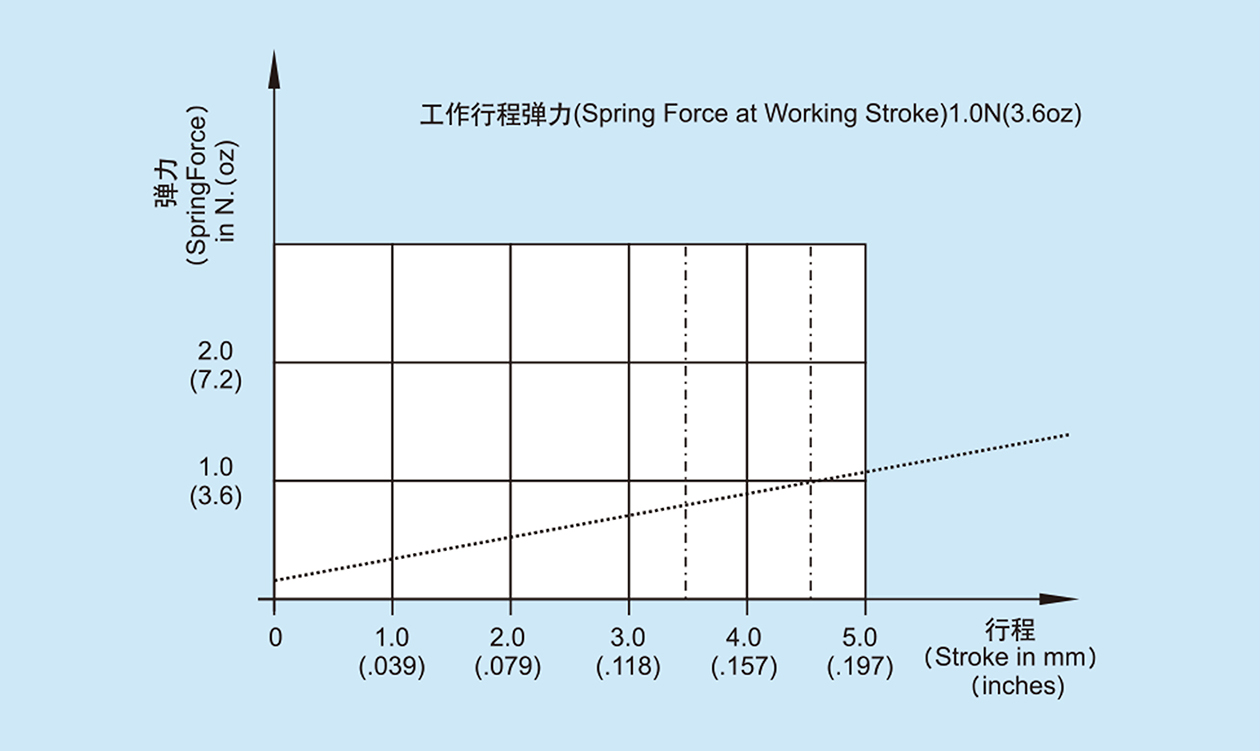

That is, we often say "wire diameter", such as 2.5 square millimeters, 4 square millimeters, etc. This is common in renovations. But it should be emphasized here that it is not the cross-sectional area of the entire line that determines the ampacity, but the cross-sectional area of the conductors inside the line. The thicker the wire, the greater the current carrying capacity.

How to maintain the high current test needle?

1. Maintenance methods of wires and connectors:

(1) The number of locking times of the SMA connector is generally about 500 times (if the number of times of use is exceeded, please try to remove it and replace it with a new one to avoid abnormal tests);

(2) When manually removing the wire, please rotate the "connector HEX part" to remove the wire or adapter, and do not pull the sleeve hard to prolong the life of the wire;

(3) When removing the wire with the torque wrench, please use the standard SMA torque wrench to lock and remove the wire;

(4) When the wire connector or universal adapter is not in use, please protect it with a protective cover to prevent damage to the connector or dust affecting the data value;

(5) Alcohol cotton should be used for wiping, cleaning, and maintaining joints at ordinary times;

(6) All wires have a small bending radius, do not exceed the size of the specification radius, so as not to damage the performance of the wire;

2. Fixture probe: maintenance method of

Please wipe and maintain with alcohol cotton every 1000 times.

3. Product service life:

(1) SMA connectors are generally used about 500 times;

(2) The fixture probe should be shown in various product specifications;

4. How does the periphery of the production measurement fit with the fixture:

(1) In order to make the test more stable, please fix the 2/4 hole probe vertically on the fixture;

(2) In order to prolong the life of the fixture probe, if it exceeds 2/3, the durability may be lost.